Without regular instrument calibration, operators expose themselves to risks like:

- Inaccurate measurements leading to compromised production

- Instrument safety risks.

- Increased downtime of malfunctioning solutions.

- Dissatisfied customers and loss business.

- A higher overall spend on operational instruments.

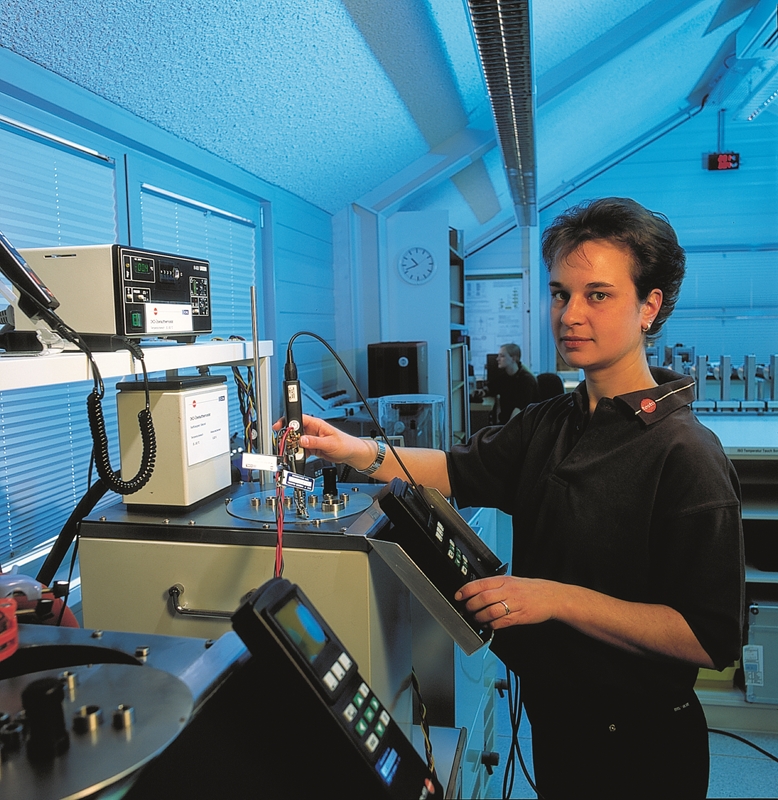

A dedicated servicing and calibration schedule for your critical measurement instruments doesn’t just reduce the chances of the above issues arising. It also means you can be more proactive with quality control and instrument use, maximising process productivity and making the most of the financial investment in your testing solutions.

Dedicated instrument calibration significantly reduces the risk of issues that can affect your operations.

Dedicated instrument calibration significantly reduces the risk of issues that can affect your operations.

The risks of irregular instrument calibration explained

The risks of inaccurate solutions from a lack of servicing and calibration can have far-reaching consequences across every application and function within your business.

Inaccurate measurements leading to compromised production – If you don’t calibrate your instruments, reduced measurement accuracy is unavoidable. This presents production issues like compromised product/process quality, increased waste and lowered productivity.

Instrument safety risks – Electrical shocks can stem solely from unserviced instruments. Aside from the potentially unsafe operation of individual measurement instruments, safety issues can also arise when data inaccuracy puts employees’ health at risk. For example, an instrument unable to accurately test particulate build up in an indoor facility leaves workers at risk of long-term respiratory issues.

Increased downtime and repair of malfunctioning solutions – Without a dedicated calibration schedule, your testing solutions can cease working accurately at any time. This leads to increased unplanned downtime while operators repair and service your instruments.

Dissatisfied customers and lost business – Business operators who identify testing instrument inaccuracy in internal production processes are generally the lucky ones. It often takes customers receiving a compromised product or clients visiting an unsafe site to address issues with a measurement solution before calibration is noted as the remedy.

A higher overall spend on instruments – Each of the above factors leads to a higher overall spend on fixing the errors stemming from a lack of instrument calibration. With a dedicated, professional service, operators can avoid these costs and ensure business-critical testing and measurement solutions stay working accurately for longer.

The Testo team can now bring some of its calibration services to Victorian customers onsite!

The Testo team can now bring some of its calibration services to Victorian customers onsite!

Testo Australia’s onsite calibration service

Our customers based in Victoria can now access our suite of temperature and electrical instrument calibration services onsite. That means less worrying about transporting your measurement solutions offsite for servicing. Less downtime as we calibrate and test your solutions for inaccuracies. No wasted productivity waiting for the instrument to be returned to you. All work can be completed in your facility, on your time, to meet the specific needs of your business.

Contact the Testo team to see the benefits of specialist onsite instrument calibration yourself!

Reduce cooking oil costs while ensuring quality

Reduce cooking oil costs while ensuring quality Expert knowledge on CO2 monitoring

Expert knowledge on CO2 monitoring Refrigeration knowledge - in 3 modules

Refrigeration knowledge - in 3 modules