Choosing the most useful tools to carry with you is an important part of a HVAC technician's job. There is a wealth of options, but in the interests of efficiency it makes sense to prioritise the equipment you will need regularly and lighten your load by leaving non-essential gear in the shed.

A thermal imaging camera may not seem like as critical a piece of equipment as some others, but longtime users can likely attest to the value of having one in their toolkit at all times. Let's take a look at a couple of the most valuable uses of thermal imagers.

Gauging performance from a distance

Whether hot or cold, the purpose of an HVAC system is to manage temperature for comfort and safety in a given site. Naturally, the key purpose of a thermal imaging camera is to provide technicians with the information they need to accurately assess the performance of a system.

Making these judgements isn't always easy, however; often the critical points of measurement are in ceilings or high up on walls where they are difficult – and potentially hazardous – to reach. Thermal imagers can be used from a distance and cover a wide area, identifying any potential issues with ease.

Thermal imagers can be used from a distance and cover a wide area.

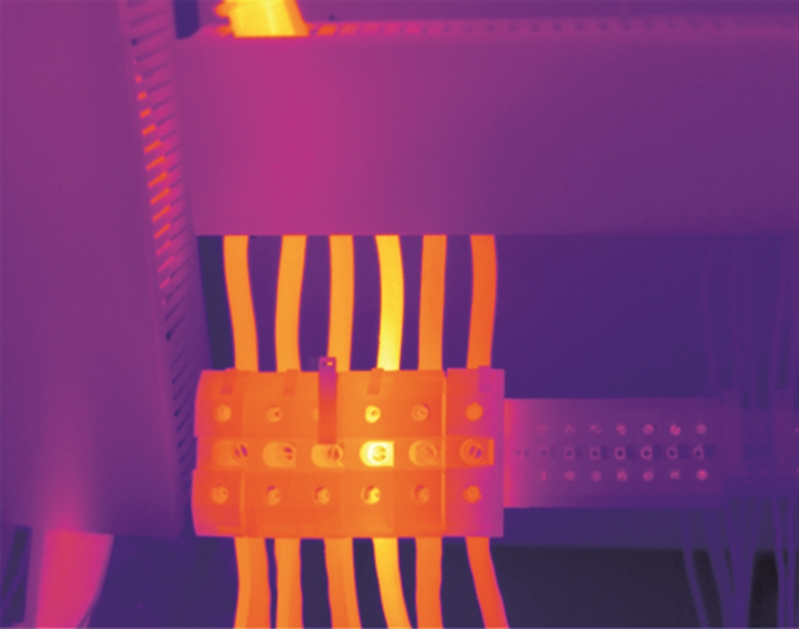

Reducing the risk of electrical issues

Any building or facility is packed with electrical components – fuses, circuit breakers and wiring – all working together to ensure power is getting where it needs to. With so many critical parts, discovering potential problems can be challenging for even the most experienced technicians.

A loose connection in an electrical component, for example, can allow for the intrusion of dirt and dust in a system, which can accumulate over time and become a significant fire hazard. Targeting areas of a building that feature a large amount of electrical equipment with your thermal imager will reveal where heat is building in the system, allowing technicians to address any problems to prevent power failure or fire.

Choosing a thermal imager

For the most precise measurements possible, the testo 872 thermal imager can detect temperature fluctuations to within 0.06oC, ensuring technicians can catch any issues early and prevent further damage. Temperature conditions are displayed on the 872's screen with automatic hot-cold spot recognition, so it's easy to identify what the problem may be and begin working on strategies to address it.

Reduce cooking oil costs while ensuring quality

Reduce cooking oil costs while ensuring quality Expert knowledge on CO2 monitoring

Expert knowledge on CO2 monitoring Refrigeration knowledge - in 3 modules

Refrigeration knowledge - in 3 modules