What if we told you the next big thing was already here?

Supply chains have long been a point of contention in turning a profit. Even companies that have figured out how to reduce the complexity of their delivery routes still contribute to the $50 billion worth of cargo lost globally each year, Inbound Logistics reported. Shipping fresh produce and perishables carries an even greater risk than transporting other products – but innovative quality management systems are helping to greatly mitigate the threat.

What is your company losing?

Cold chains are inherently unstable. Across the food distribution industry, studies have found that the conditions inventory is transported in is often unstable, resulting in varied temperature swings, according to a Comprehensive Reviews' study in Food Science and Food Safety. Given that food is always decaying, these environmental changes only serve to speed up the process.

Around one-third of all fresh fruits and vegetables are ultimately thrown away due to poor quality each year, with much of that waste attributed to ineffective food logistics outbound strategies, a study in PubMed Central found. By integrating the testo Saveris Retail platform, companies can leverage real-time insight over food quality during transportation to significantly reduce loss and improve profit margins.

Take action today

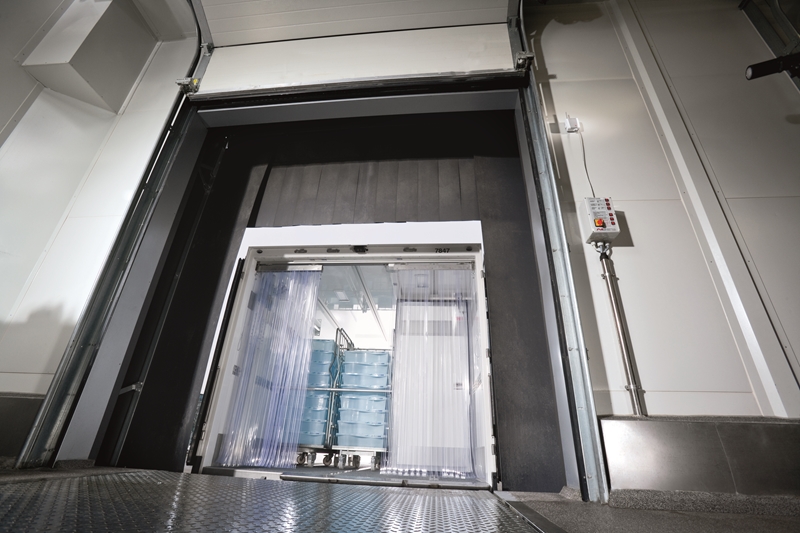

The cold chain has historically proved to be unable to guarantee the fresh delivery of food on its own. But now, distribution centres can leverage data loggers placed inside storage chambers to get real-time alerts on variations in temperature. This allows personnel to act immediately to remedy the issue, which cuts down the chance that the inventory becomes waste before reaching grocers.

Testo Saveris Retail is a platform that digitises quality management to create an automated system for monitoring cold chain environments from warehouse to recipient. This allows the transport company to gain insight into their methods and provide transparency to the customer. On the other end, the level of care being taken is likely to improve the chances that the shipment arrives fresh.

The majority of industries are using Internet of Things (IoT) technology in some shape or form, and logistics organisations' new solution is finally here. Testo Saveris Retail helps companies create a more intelligent cold chain with improved transparency at the heart of it all. Contact a Testo representative today to learn more.

Reduce cooking oil costs while ensuring quality

Reduce cooking oil costs while ensuring quality Expert knowledge on CO2 monitoring

Expert knowledge on CO2 monitoring Refrigeration knowledge - in 3 modules

Refrigeration knowledge - in 3 modules